What many think may be the next big thing in manufacturing is already happening in the I-77 Corridor. It’s micromanufacturing, which is just what it sounds like: small- to medium-sized, agile operations that can quickly produce products that traditionally require massive capital and space to achieve anything close to the scale needed to make such a venture viable and profitable.

Vehicles are the perfect example. Rock Hill in York County was chosen by Arrival, a British startup that uses micromanufacturing techniques to produce, in this case, electric buses. Instead of a massive factory that covers acres, Arrival is setting up shop in a 193,000-square-foot spec building, with an estimated $46 million in CapEx and 240 new jobs.

Rather than a production line, Arrival will use a cell-based assembly method that will allow it to build the buses as ordered, and to quickly transition to any other vehicle it makes, and it plans to source materials from a localized supply chain, adding to efficiency and lowering environmental impact.

That modular approach taps into another trend that the I-77 Corridor is positioned to accommodate: onshoring. The pandemic has demonstrated the fragility of global supply lines in ways that, even when all is normal again, makes the ability to procure materials domestically more attractive going forward.

Especially when less of it is needed. Microfactories take the concept of just-in-time inventory that revolutionized auto production a generation ago to a new level. Customized, just-in-time production of exactly what a customer wants make one-offs possible at a scale previously unattainable.

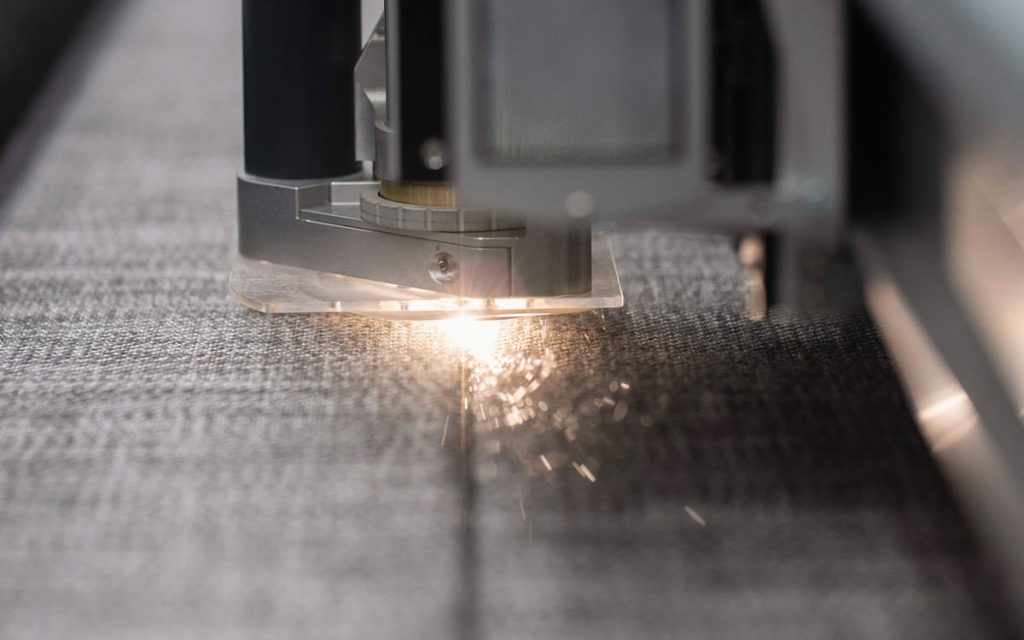

This kind of innovative production lends itself to a high return on investment that extends well beyond vehicle manufacturing into realms such as textiles and electronics, including consumer goods and industrial products.

However, it still requires a skilled, motivated workforce, a traditional requirement that the Corridor continues to fill as companies and schools – including high schools and technical and four-year colleges – regularly adapt to provide the general and company-specific skills new and expanding firms need to succeed.

The Corridor already hosts a growing number of firms engaged in leading-edge manufacturing technologies, including some of the pioneers in 3D printing that also are revolutionizing manufacturing.

Meanwhile, the Charlotte and Columbia markets that anchor the I-77 corridor account for a workforce of about 1.3 million people, and nearly half the nation’s population lives within a day’s drive.

All these factors make the I-77 Corridor a strong candidate for microfactories to gain a foothold, in all their iterations, as the region and these technologies will continue to grow together.